AKIS MACHINERY MOTOR CASTING INDUSTRY AND TRADING CO., LTD

AKIS, whose technology is based on 1978, started its activity in elevator sector by continuing to combine its experience and knowledge with new investments in integrated system.

The process began with geared machine motor production in 1966 and continued with the production of elevator control panel with frequency-control system in 2007. In the following period, AKIS started serial production by completing the gearless machine project which developed by AKIS at TEKNOKENT in 2010. And in 2011 AKIS started the serial production of the first and only long-distance, high speed flexible cable in Turkey.

Today, AKIS became one of the most important institutions of Turkey and of the sector by continuously investing in its technology. AKIS continues manufacturing the products with an integrated system in its facilities which are in Konya Organized Industrial Zone on 40.000 m² closed area and 106.000 m² total production area.

Automatic molding modern foundry, high technology machining department and conceitful quality control laboratories lead AKIS to perform the production in international standards. AKIS attaches great importance to research and development. In this context, AKIS continuously increases product range and product efficiency.

AKIS manufactures its every product in accordance with international standards. AKIS separately tests and analyzes every single part of the products in its laboratories. AKIS has many national and international quality certificates such as ISO 9001:2008, CE, GOST, TSEK and TSE.

AKIS is the biggest elevator motor manufacturer in Turkey and in the region. AKIS’s high production capacity greatly meets the demands of elevator sector. Today, AKIS exports to more than 40 countries in 5 different continents.

MOTORS FOR LIFTING SOLUTIONS

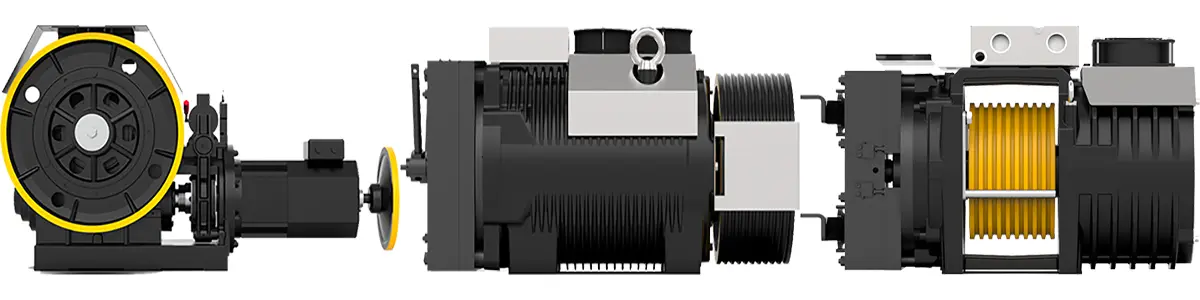

SICOR is an Italian company specialized in the design and production of traditional reducers and gearless machines for lifts. In over forty years of activity, it has become a global reference point in the sector for the quality of its products, the completeness of the range, the ability to know how to interpret and anticipate changes and new market demands. The company headquarters integrates offices and a production plant into a single complex and it is in Rovereto in the province of Trento.

It’s a structured and modern industrial complex with a very high level of automation able to guarantee quality, efficiency, and speed of production, in compliance with the highest safety standards for workers. SICOR motors are an expression of guarantee and quality, a market leadership recognized worldwide, with such an awareness that some acronyms and codes of motors have become identifiers for the designers of the type of product.

SICOR represents a model of excellence of Italian mechatronics, a successful path that sees a constant evolution in the quality of the product and a continuous growth of the service towards the satisfaction of the needs of design customization and technical assistance.

About Us

Our company, which was established in 2007 in order to contribute to the growing and developing urban life day by day, produces elevator floor, cabin panels and emergency call systems. Butkon Elevator provides products and services to its business partners with a staff of 170 engineers and experts by determining the needs of urban mobility together with its business partners and benefiting from the efficiency of technology. Thanks to its technological production infrastructure, butkon, which makes development and innovation continuous with its R&D studies, can offer the flexibility and customization it needs to its business partners.

OUR QUALITY POLICY

It is to establish total quality awareness by ensuring that everyone from our suppliers to our customers adopts the belief that quality is a process that is constantly developing and showing continuity. To stand out with our customer-oriented approach and quality, to always be a pioneer, sought-after and innovative organization in the sector. While engaging in all our activities; To comply with legal regulations, legal regulations, and customer requirements, to be privileged in the sector with “Butkon Quality” with its deadline, cost, and technological features in the projects we carry out with all our customers, suppliers and business partners. To attach importance to teamwork, to place quality awareness in all employees in this direction, to respect society and the environment,

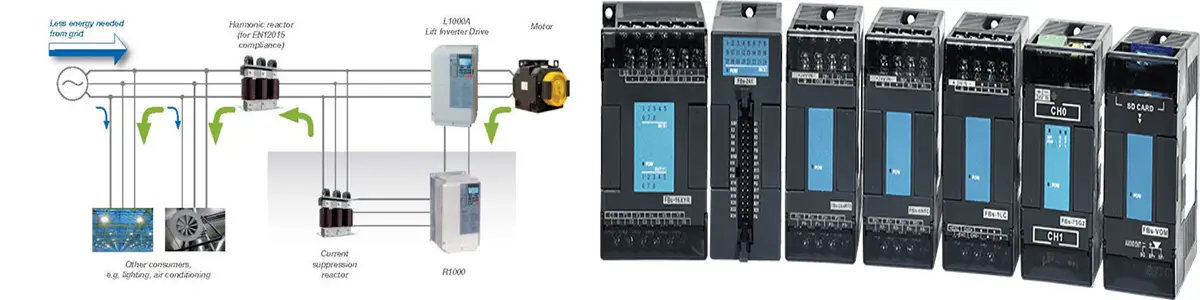

FATEK Automation Corp. was established in 1992 in Taiwan by a group of engineers engaged in PLC design and development for many years. Since its establishment, FATEK has strived for R&D in order to provide high-quality, high-function and user-friendly automatic control products. The product line focuses on PLC, HMI, IoT solutions, SCADA application software, OPC Server and power supply, etc. With our endeavors for decades, we are now well-recognized in the industry for high quality and reliability with the brand name of “FATEK.” While maintaining stability and dependability, FATEK also continuously engages in R&D and innovation to expand a broader application field, striving to becoming a professional, reliable, and holistic solution provider.

QUALITY AND SERVICE

FATEK has always adhered to the spirit of sustainable operation. FATEK has a complete quality management system. We highly value and insist on doing the best on details and key points, from selection and inspection of materials to be used, the process and details of the production assembly, and testing and verification before delivery to product tracking after delivery, to ensure that our products can meet our strict quality requirements. Because FATEK knows well that the most fundamental way to gain customer’s confidence on the brand name of “FATEK,” we only provide excellent quality and highly reliable products.

In the beginning of FATEK’s establishment, industrial control products were almost monopolized by brands of all advanced countries. It was then not easy for FATEK to persuade customers to bring our products into their applications, even though they were high-performance and reliable products. Therefore, FATEK stepped up the on-site applications of many sectors to deeply understand what customer’s needs and expectations were. Then, we optimized and upgraded the controller’s functions by consolidating customer’s feedbacks, successfully acquiring customer’s trust and recognition.

About Schneider Electric

Our mission is to be your digital partner for Sustainability and Efficiency. We drive digital transformation by integrating world-leading process and energy technologies, end-point to cloud connecting products, controls, software, and services, across the entire lifecycle, enabling integrated company management, for homes, buildings, data centers, infrastructure, and industries.

We drive digital transformation by integrating world-leading process and energy technologies to realize the full efficiency and sustainability opportunities for your business. We provide end-point to cloud integration connecting products, controls, software and services. We enable lifecycle solutions from design and build to operate and maintain phases through a digital twin. We deliver capabilities to transform from site-to-site to an integrated company management. Our integrated solutions are built with safety, reliability and cybersecurity for your homes, buildings, data centers, infrastructure and industries.

Vital Elevator Trade Company was established in 2012 and started its activities. Our company, which has been operating in an area of 13.000 m2 since 2019, continues to increase it’s production capacity by exporting its products to more than 50 countries in Europe, Asia, Africa and South America without sacrificing quality and taking into account customer demands.

At this point, the production of elevator automatic doors, cabins, cabin suspensions, weight chassis, machine chassis, control panels continue in our facility.

Based on project-based work; Elevator requests submitted to us are projected and enter the production phase, productions in accordance with the project are carried out by us, the project is completed by supplying the items not produced in our factory and shipped to the customer as a package.

Our company is constantly increasing the necessary infrastructure and production standards in order to provide better quality and faster service to our customers. Our company, which attaches great importance to technical support at every stage of production and after production, gives priority to R&D studies by considering customer satisfaction.

As a result, Vital Elevator continues its services without leaving its Quality and Trust oriented principles. It will continue to serve with the same principles in the future.

About Yaskawa

We place value on manufacturing and development of human resources and create new markets.

Yaskawa Electric has always provided support to the leading business across the ages by transforming as “a MOTOR manufacturer”, “an AUTOMATION company” to “a MECHATRONICS company” based on its management philosophy of contributing to the development of society and the welfare of humankind through the performance of its business since the establishment in 1915.

We propose the new solution concept “i³-Mechatronics” to realize continuous improvements in customers’ productivity by integrating mechatronics products with utilization of digital data. We strengthen our core businesses of servo motor, controller, AC drives and industrial robots using these core technologies to the full, and evolve mechatronics using digital data. We achieve revolutionary industrial automation and are committed to contributing to solve customers’ business challenges.